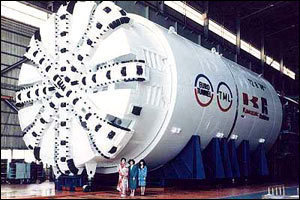

Size of a Tunnel Boring Machine

A tunnel boring machine or TBM is used  for excavating tunnels. These machines are capable of digging in rock, sand and other materials. After it is done digging, the result will be a smooth wall. The TBM is made of numerous rotating cutting wheels set on a shield. The shield size varies from 3 to 60 feet (0.9 to 18 m).

for excavating tunnels. These machines are capable of digging in rock, sand and other materials. After it is done digging, the result will be a smooth wall. The TBM is made of numerous rotating cutting wheels set on a shield. The shield size varies from 3 to 60 feet (0.9 to 18 m).

Types and Sizes

Tunnel boring machine sizes vary, but there are two shield models available. The single models are suitable for hard rock strata. The double shielded variants are utilized for unstable strata. However, most of these machines are tailored made for specific tasks. For this reason, every TBM will have its own features, dimensions and other specs.

Most TBMs can measure bores with their micrometers. Their sizes vary from 50 mm to 2000 mm in diameter. A horizontal TBM can have specs like a 100 mm spindle diameter, an 1100Nm torque, and various spindle speeds.

The speed varies from 10 – 1100 RPM. The boring diameter can be anywhere from 65-140 mm. The spindle specs can range from 250r/ min and 380r/ min.

How a TBM Works

The following shows how the tunnel boring machine works. This example is for hard rocks. The tunnel boring machine size will also affect the way it operates.

The TBM head is pressed against the sides of the rock. The cutting beads will strike the rock face. The force applied varies, but 26 tons is about the average.

After the rocks are broken, these are collected in bucket wheels. They are placed in the conveyor belt. These are put in the back of the TBM. Behind the cutting head, the tunnel walls are placed at the back of the machine.

The tunnels walls are secured at the back of the cutting head. Drills are used to make openings in the rock. To be used as anchors, they can reach lengths of 13 feet (3.9 m). Depending on the tunnel boring machine, the drilled holes may be bigger or smaller.

A mesh placing machine goes over the anchor drill placing apparatus. This is a safety precaution against falling rocks. Note: the securing measure used will be based on the site geological features.The grippers move and press against the tunnel walls.

As stated, the tunnel boring machine sizes and specifications have to be determined before the machine is used. Unless this is done, mistakes during the tunneling can occur.