Countersink Dimensions

To find the right countersink measurement you  must be aware of the screw size you are using. The figures you get will determine the countersink drill type that must be used.

must be aware of the screw size you are using. The figures you get will determine the countersink drill type that must be used.

Countersink Size Guide

If you are using screw size #2 the countersink cut would be 1/4" and the taper drill 3/32” (hardwood) and 5/64" (softwood). For screw size #4, the cut is 1/4" and the taper drill is 7/64" (hardwood) and 3/32" (softwood).

For screw size #6 the cut is 5/16" and taper drill size is 9/64" (hardwood) and 1/8" (softwood). For #8the cut is 3/8" and the taper drill is 11/64" hardwood and 5/32" softwood.

For #10, the countersink cut is 7/16" and the drill is 13/64" hardwood and 3/16" softwood. For #12, the countersink cut is 1/2"; taper drill hardwood is 7/32", softwood: 13/64".

How to Countersink a Screw

Step 1

Get the screw length and the pilot hole diameter. This will decide what regular or countersink drill to use. If you can’t figure it out, the people at the hardware store can help you.

Step 2

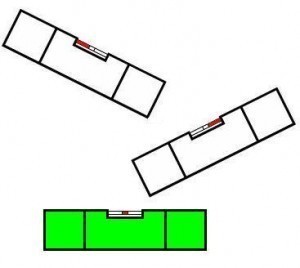

Mark the spot where the initial screw will be placed. If using a regular drill, note the pilot depth with a masking tape. If using a countersink drill bit, this won’t be necessary.

Step 3

Screw in the screw with the hand drill. If using a regular drill, a bit more force will be needed than a countersink drill. Now fill the recess with some wood putty. Scrape off the top until it is even.

Countersinking Holes in Metal

Step 1

Put on your safety glasses. Position the countersink arbor in the drill motor chuck. Secure the chuck.

Step 2

Put the countersink bit center in the hole. Put pressure on the drill handle. Depress the trigger to start drilling. When the drill edges meets the surface metal, stop. This should be done regardless of the countersink size.

Step 3

Put the screw in. Run your hand over the metal surface. If the screw still protrudes, take off the screw and drill again.

Step 4

Put the countersink drill in the drilled hole’s other side. Drill quickly to get rid of burrs. This will secure the metal tight.

It is very important to be aware of the countersink sizes before starting the job. Unless you do so, you could end up with a lot of problems. The guide above can be used as reference. If you are having problems, talk with the people in the hardware store.