PVC Pipe Sizes

The (polyvinyl chloride) PVC pipe sizes and the  CPVC (chlorinated polyvinyl chloride pipe) are made using the NPS sizes. The NPS is the US standard used for pipes, be it for high / low pressures / temperatures. The pipe dimensions are measured by the nominal size (in inches) and the schedule. The European equivalent is DN (diametre nominal).

CPVC (chlorinated polyvinyl chloride pipe) are made using the NPS sizes. The NPS is the US standard used for pipes, be it for high / low pressures / temperatures. The pipe dimensions are measured by the nominal size (in inches) and the schedule. The European equivalent is DN (diametre nominal).

How the Measurements are Taken

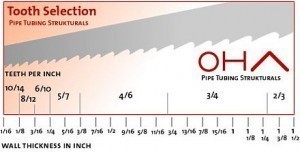

The pipe wall thickness and the pipe outer wall diameter (OD) can be determined using the NPS and the schedule. For instance, the NPS 14 sch 40 has a 14 inch outside diameter. The wall thickness is 0.437 inches.

However, the OD and NPS values do not always correspond. For the nominal pipe size and OD 1/8 to 12 inches, the values are not the same. For instance, the NPS 12 pipe has an OD of 12.7 inches. In this case, tables should be used for reference. But for NPS 14 and above, the OD is the same. That is, an NPS 14 really has a 14 OD.

Reason for the PVC Pipe Size Discrepancy

The reason for the inconsistency at the 1/8 to 12 inch size is that NPS values were initially meant to provide the same inside diameter (ID) according to the established wall standard. But over time, the wall thickness changed. This meant the NPS became only became obliquely linked to OD and ID.

Other Information

For any particular NPS, the OD will remain the same. The wall thickness however, goes up with the schedule. For a specified schedule, the OD dimensions increase along with the NPS. The wall thickness however, will not change.

Utilizing the ASME B31.3 Process Piping regulations, it will be shown that an increase in NPS with a fixed schedule will lead to a decrease in pressure rating.

IPS

In some cases, pipe schedules are referred to as STD (standard wall), XS (extra strong) and XXS (double extra strong). These terms are from an older system called the IPS. The IPS number is similar to the NPS number.

The STD is the same as schedule 40S, and the 40S is equivalent to NPS 40 1/8 to NPS 10. XS is equal to schedule 80S. 80S is the same as 80 NPS (1/8 to 8). The XXS is almost always thicker than sch 160 but various definitions exist.

Usage

Nearly 50% of the polyvinyl chloride made is for use in pipes. In the US alone, it accounts for nearly 70% of the water distribution market. For sanitary pipe work, the rate is almost 80%.

The reason for its popularity is its durability, lightness and low reactivity. Another advantage is that it can be mixed with different kinds of solvent cements. In Canada, PVC pipes make up the biggest amount of material used for distributing drinking water. PVC is also used in many other countries.

While there are some disparities, most of the PVC pipe sizes used is standardized. It is just as well, because it has become very important for safe delivery of drinking water.