ANSI Flange Dimensions

ANSI flange dimensions are standards used for steam process systems and other sectors in the industrial market that manage air and gas. The proceeding info will indicate common sizes used.

Size Guide

ANSI 125/150 has a flange diameter of 25″ / 635 mm, while for ANSI 300 the diameter is 28″ / 711 mm. The diameters for ANSI 600, 900 and 1500 are 29 1/4″ / 743 mm, 31″ / 787 mm and 36″ / 914 mm. For BS10 Table D it is 25 1/4″ / 641 mm; for Table E it is 25 1/4″ / 641 mm and for BS10 Table F it is 26 1/2″ / 673 mm.

Use

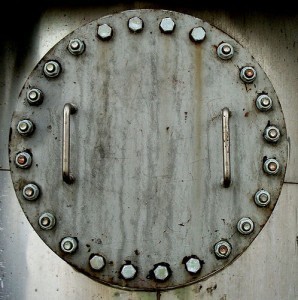

Whatever the ANSI flange dimensions are, they are frequently used to connect other flanges or pipes together. Those made for gas and oil are designed to work under intense pressure. The standards were set by ANSI so the units could be evaluated first by manufacturers.

The standards hinge on the PSI (pressure in pounds per second per inch). This is based on the flange size in inches. The dimensions and pressure depend on the pipe (bolted, threaded or welded).

Composition and Specifications

Flanges can be built with steel or cast iron. They are designed to work for a specific class. The requirements and specifications depend on the class. Factors that influence its features include coating material, the size of the nut and bolt and pressure-temperature rating among others.

About Pipe Flanges

Pipe flanges are rated for maximum strength and resistance to corrosion. The following information will shed more light on them.

What is a Cast Flange?

These are components of the line section. They are configured so connecting with other flanges is easy. Cast flanges are noted for their pressure resistance. The biggest drawback with these is if the flange has to be replaced, the whole line must be replaced as well.

What is a Ring Flange?

These are separate line components. It has a flared end with rings around it. This keeps it sealed when linked to a second flange. With this variant, various line diameters can be attached. Here, the flange works as a reducer. Unlike the cast type, there is no need to replace the whole section. This is crucial when it comes to corrosive and caustic media.

Because there are several ANSI flange dimensions, it is imperative that the right type be used. Aside from the diameter, the PCD (pitch circle diameter) is also considered. This is the circle diameter which enters the bolt holes.